AF-Booster System®

AF-Booster System®:

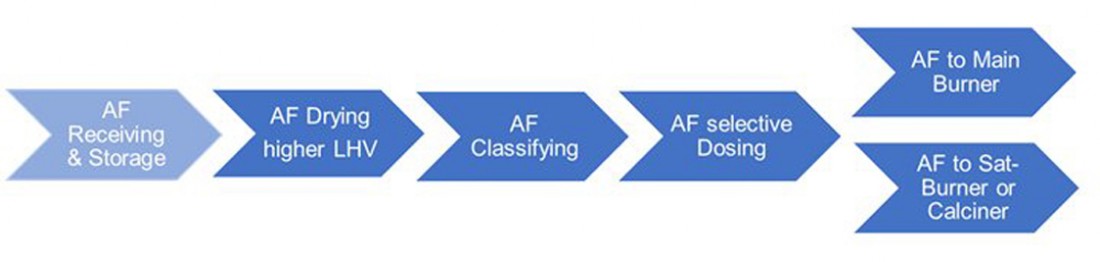

The AF-Booster System® allows an increase of AF while reducing CO2 Emissions along with the stabilization of the pyro-process for clinker production.

HOW IT WORKS:

Maximize RDF use over 90% TSR with our new type of system that is using waste heat for step-wise drying of RDF and feeds the fine fraction to the kiln burner and the coarse fraction to the AF satellite injector or to the calciner, according to adjusted fuel size. The dry and classified AF-fractions with increased LHV are prepared most effective for the enhanced combustion conditions at the kiln.

The result is an optimized pyroprocess for stable burnability to avoid longer double-flames and high kiln inlet temperatures. It provides the required retention time and increase the clinker quality while reducing your OPEX and CO2 emissions.

That technology allows to consider also biomass (CO2 neutral) or other residues with low LHV to be processed and classified for the most fitting combustion location at the kiln line.

The AF-Booster System® (applied for patent), will be specific designed and implemented to the existing pyroprocess in your cement plant.

This process is designed to increase the combustion quality and the TSR, while working with a stabilized kiln operation. The usual RDF can be taken for the AF-Booster System® and it is designed to be implemented to existing or new RDF handling systems within the cement plant.

• Reduce your fuel costs

• Reduce CO2 certificates

• Be more flexible on the AF-fuel market

• Stabilize the process even with high TSR

unclassified SRF, as received

coarse fraction of SRF, after classifyer

CAPEX: ROI within around 1 year